PRODUCTS

COMPACT SPINNING SYSTEMS

To meet every customers requirement, Swinsol offers widely compatible compact spinning systems and solutions individually adjusted to your machine. We provide the highest swiss quality components and offer the highest possible profitability and sustainability among compact spinning units. Our Recompact Systems are very unique: They are the only ones making use of real controlled traversing and using a 3-Pathway-Technology using 18mm of the cots width. After the quick and easy installation through our well-trained service staff, the Recompact Line provides you with the best possible yarn quality, the lowest possible downtime and maintenance which leads to a significantly higher production output – with no additional energy consumption. A rapid and seamless production are guaranteed. We also offer upgrades from existing systems at a competitive cost.

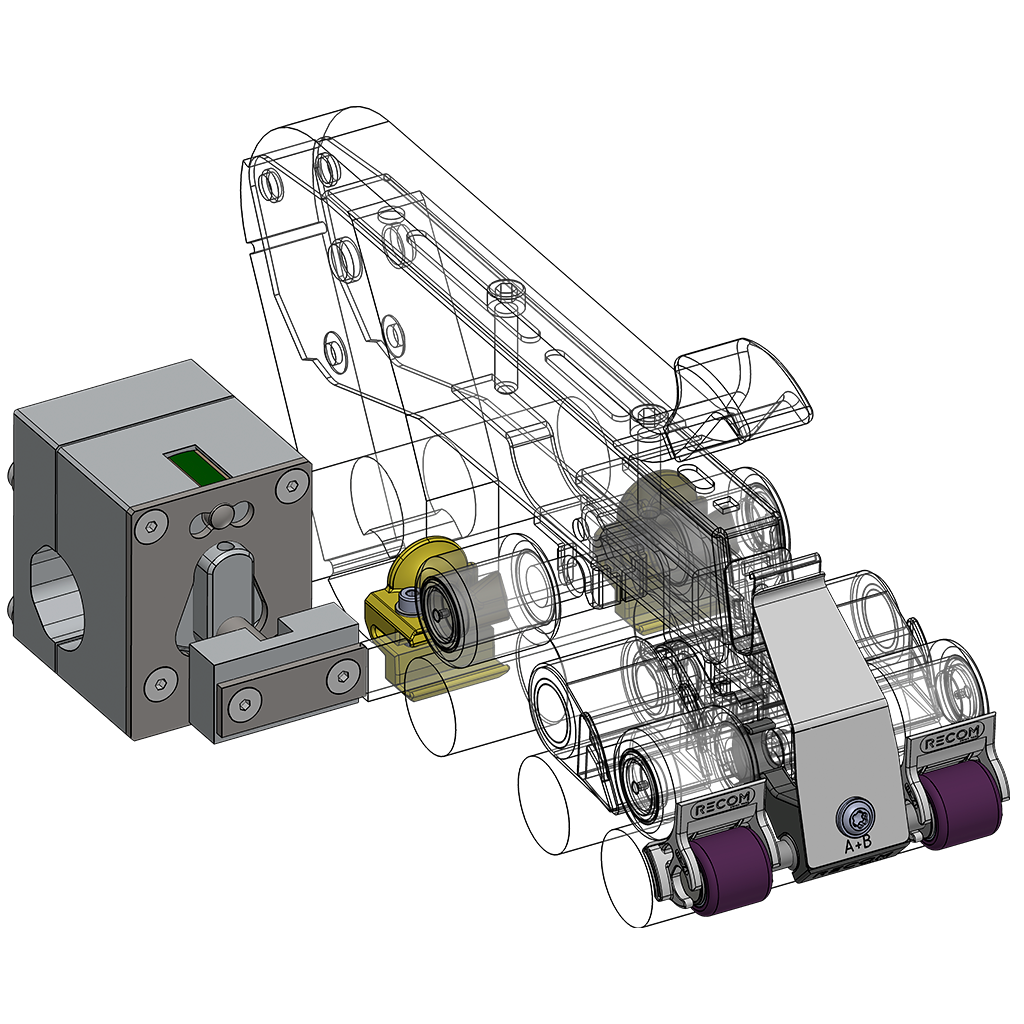

RECOMPACT 3.T

Recompact 3.T (=Traversing)

The only true traversing compacting system available for about the same cost as conventional spinning. Decide between automatic or manual controlled traversing, and save up on manpower and personel costs. 3.T provides the same advantages as Recompact 3.0, but makes traversing even more efficient. Special recommendation to American and Turkish spinners, to make the absolut most of their ringframes.

RECOMPACT 3.0

Latest up-to-date technology

The Recompact 3.0 System is the latest compact spinning system designed to bring innovation to your spinning mill. For the first time, there is no downtime while compact spinning, the longest lifetime in the industry by using 18mm width of cots with our controlled traversing 3 – Pathway technology and lightning fast maintenance.

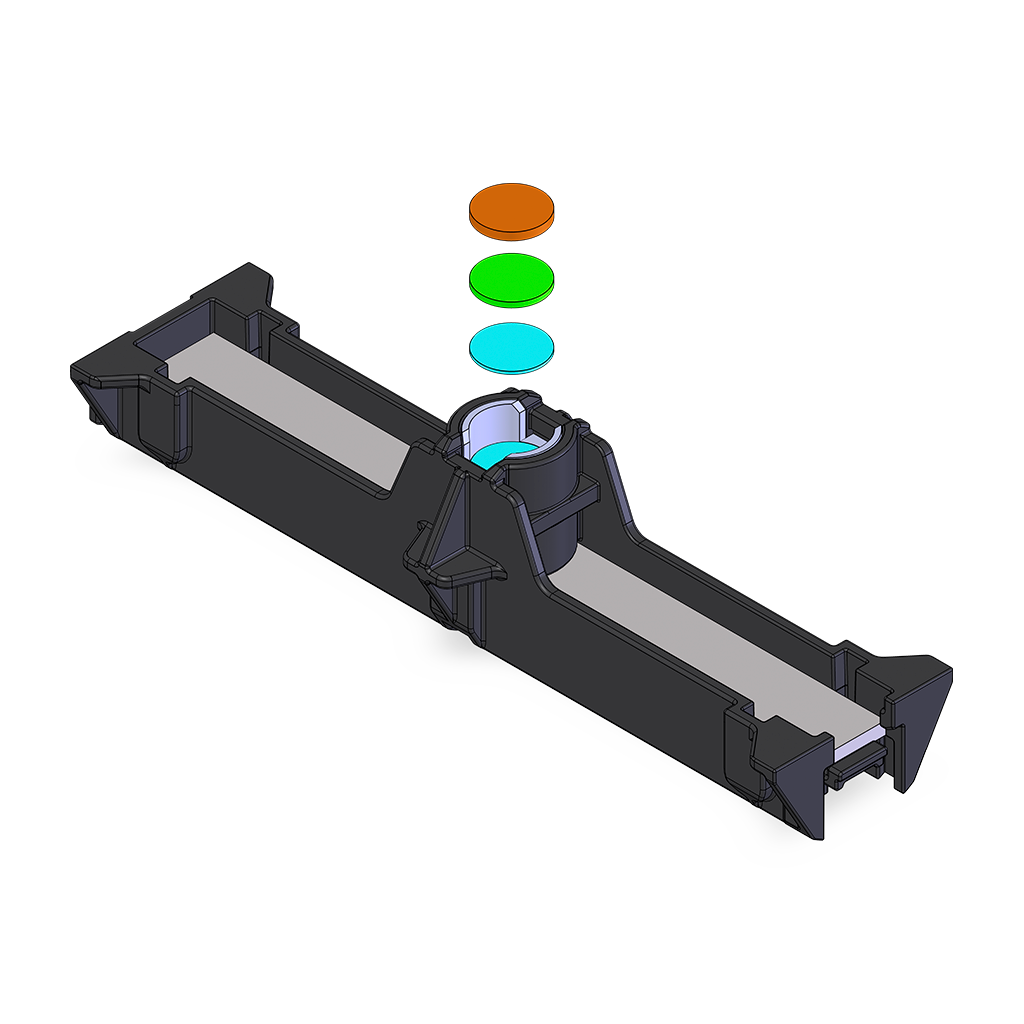

RECOMPACT 2.0

Highest Standard in Compact Spinning

The Recompact 2.0 System is the core unit for compact spinning. It delivers the best yarn quality, increases the production volume significantly and doesn‘t require any additional power.

P3-1 Top Arm Modernization Kit

SpringUnit®

SpringUnit® – P3-1 Top Arm Modernization

The P3-1 toparm modification replaces the suction/air-tube system in the hexagonal rod with a mechanical solution to provide individually adjusted pressure settinsg to each toparm. Based on a mechanical principle, no energy or air is required, thus no leaking. Additionally 10 years+ guaranteed lifetime, individually adjustable pressure per toparm at any time. The SpringUnit guarantees exact pressure load on the toparm and secures an equally distributed pressure on the left and right roller at any time. Readjust, if a toparm gets slightly deformed over its lifetime and restore its full potential in yarn quality – a true novelty in the ring spinning world. Supports sustainability and energy-efficiency.

OUR ADVANTAGES

IN-HOUSE ENGINEERING

FAST DELIVERY

COST INNOVATION

FAST RESPONSE TIME

SWISS MADE PRECISION

HIGH QUALITY YARN CREATION

FREE SPINNING TRIALS

SATISFACTION GUARANTEE

Swinsol AG

Au SG

Switzerland

SWINSOL MAKiNE SANAYi VE TiCARET LiMiTED SiRKETi

4 Dulkadioglu

Kahramanmaras

Türkiye